Vibration and Failure Analysis: Protecting Spindle Performance

Why Spindle Analysis Matters

In high-performance machining, every detail counts. Excess vibration or hidden spindle defects can lead to poor surface finishes, tool wear, or even catastrophic breakdowns. Without proper analysis, these small issues quickly become costly problems.

That’s where vibration analysis and failure analysis from Centerline, Inc. come in. These advanced services pinpoint the root cause of spindle problems, so you can take corrective action before productivity suffers.

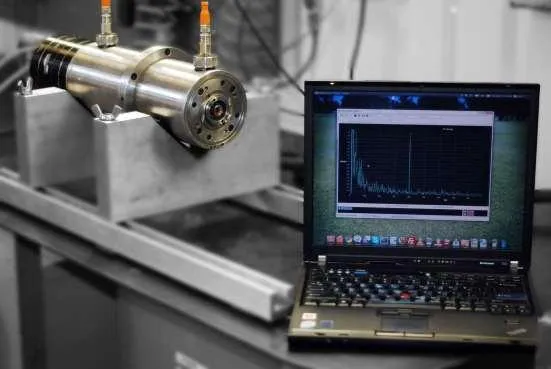

Vibration Analysis: Detecting Problems Before They Grow

Vibration analysis measures how a spindle behaves while in operation. By using advanced sensors and software, our technicians can:

Detect imbalance, misalignment, or bearing defects

Identify early-stage spindle issues before failure occurs

Improve machine accuracy and tool life

Reduce chatter and poor surface finishes

The result? A smoother, more reliable spindle that runs at peak performance.

Failure Analysis: Getting to the Root Cause

When a spindle fails, simply repairing it isn’t enough. Without knowing why it failed, the problem may repeat itself. Centerline’s failure analysis digs deep into the cause of spindle breakdowns.

This process includes:

Comprehensive inspection and testing

Identifying wear patterns, contamination, or material fatigue

Root cause reporting with actionable recommendations

By understanding the “why” behind the failure, you can prevent the same issue from happening again — saving both time and money.

Benefits of Professional Spindle Analysis

Reduced downtime and unexpected failures

Increased spindle lifespan

Better part quality and surface finishes

Lower maintenance costs through predictive insights

Trust Centerline, Inc. for Precision Analysis

Spindle problems aren’t always obvious until it’s too late. With vibration analysis and failure analysis from Centerline, Inc., you’ll know exactly what’s happening inside your spindle — and how to fix it.

Call to Action:

Don’t wait for a breakdown. Contact Centerline, Inc. today for spindle vibration and failure analysis you can trust.